Outlet screens and directional nozzles can be fitted by divers; however the appropriate pipe-work will need to be isolated for the installation period as a safety precaution.

Concrete walls and floors can be drilled underwater to fit SS anchor bolts and base areas can be effectively sealed using potable approved epoxies.

Adaptor plates can be made onsite from HDPE to suit any unusual flange patterns encountered during the installation process.

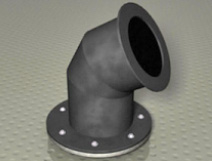

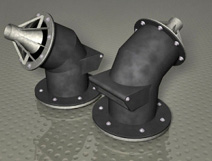

Directional Nozzles

Directional nozzles place inlet water into a pre-determined pattern to prevent short-circuiting and sediment disturbance, while maintaining an even mix of stored water to prevent ageing and deterioration.

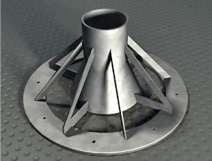

Ram Tube

The Ram Tube has been designed to improve both water quality and safety. It is attached to the discharge point of Directional nozzles and Two Way nozzles to increase the entrained water flow, whilst providing a safety screen for divers.

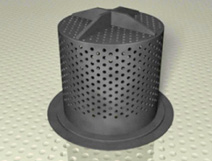

Safety Screen HDPE

Many outlets are level with the floor area, allowing sediments to enter the pipework. Our safety screens include a riser area at the base and the correct amount of holes to remain self-cleaning, while not restricting the outlet penetration.

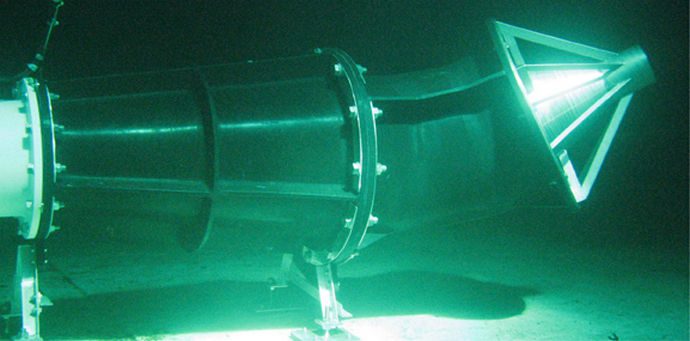

Two Way Nozzle with Ram Tube

An alternative to fitting additional pipework into the tank has become available. A combined inlet/outlet nozzle, constructed from Stainless Steel or HDPE solves most tank blending problems and requires no further energy or maintenance once fitted.